They set the pace for high productivity.

If greater size and load capacity are what you need, the T-M Vacuum Pacer Series high-temperature, high vacuum furnaces will satisfy your heat-treating requirements.

The Pacer’s oversized all-stainless steel chamber allows you to temper, harden, stress relieve, austenitize, anneal, sinter, bond, braze, and perform many other custom heat treating processes on large loads. These high vacuum furnaces come with many standard features such as our three-zone heat control and electro-pneumatically operated Heat Pack door shield assembly, creating a precision heating environment is created for perfect temperature uniformity.

Equipped with a unique high-speed pumping system, the Pacer vacuum furnaces quickly reach high-vacuum for maximum processing time. Even cool downs are fast and efficient, as the Pacer comes standard with a 25 HP inert gas Quick Cool System, in order to rapidly, yet precisely cool the chamber and ready it for the next load.

The Pacer high vacuum furnaces have automatic control system that requires no operator to monitor the process. The vacuum furnaces are fully contained units with no exposed wires, cables, or pumps, allowing for quick and easy installation in your facility. The Pacer is assembled when it reaches your plant, and attaching basic utilities is all that is necessary. With a removable Hot Zone, the minimal maintenance is simple and fast.

For heat treating vacuum furnaces with up to 24" x 24" x48" work zones, ask about our Performer and Heat Treat Series.

Temperature Capabilities and Controllability

10 series 1000°C (1832°F)

13 series 1315°C (2400°F)

14.5 series 1415°C (2650°F)

16.5 series 1650°C (3000°F)

20 series 2000°C (3632°F)

- +/- 1 degree controllability

- < +/- 5°C temperature uniformity

- Solid State Power Supply regulation

- 3-zone heat control with independent PID loop control

Vacuum Pumping System

- Standard pump down time*

- To 0.1 Torr – 8 minutes

- 10-5 Torr Scale – 20.5 minutes

- High-Vacuum Valve: T-M Right 16" Angle Poppet Valve

- 500mm diffusion pump – net pumping speed: 12,000 l/s

- 357/135 cfm mechanical roughing & backing pump

- 7 cfm mechanical hold pump

Available for Pacer High Vacuum Furnaces:

- Upgraded pumping systems - Mechanical, dry, diffusion, cryogenic, and turbo-molecular

- Mechanically refrigerated, optically-dense, cold trap in roughing line or liquid nitrogen cryotrap in high-vacuum line (for prevention of hydrocarbon contamination)

Inert Gas and Quick Cool System

- 25 HP blower – 10,000 cfm free air displacement

- Gas/water heat exchanger

- 40 nozzles directing quick-cool gas onto workload

- Integral with furnace chamber, no externally mounted components

Available:

- Multiple process gas capability

System Controls for Pacer High Vacuum Furnaces

- The system has state-of-the-art full computer control as standard, enabling automatic control of all system functions. System operation is defined by user created recipes which are stored on the system. More than 30 user friendly screens display all set points and operating data. Process parameter can be accessed and stored on the system in real time for historical reference or as customer required documentation. Operating parameters are displayed on the system’s 17" flat panel touch screen for the operator’s ready reference. Full data logging with print capability out is standard.

- Over-temperature control

- Digital vacuum display

- Center of load thermocouple standard

Available:

- Multiple-survey thermocouples

- Multiple mass flow controller

- 100% Hydrogen partial pressure operation

- Controlled cooling

Operating Pressure Range

- High-vacuum to 2 bar (higher pressures available)

- Working pressure at maximum temperature: high-vacuum to 1 torr (higher pressures available)

- Capable of pressures between atmosphere and 2-bar (for quick cool use)

- 6 bar available

Hot Zone Construction

- Usable work zone 18" W x 18" H x 30" D (36" D available)

- Usable work zone volume of 5.63 cubic feet

- Work load capacity 500 lbs (higher capacity available)

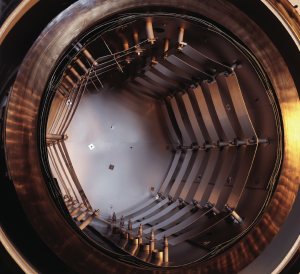

- Round, horizontally-mounted Hot Zone comprised of six (6) high temp/low resistance molybdenum 3" band heater elements

- Heat shielding is composed of molybdenum layers backed by stainless steel layers in stainless steel containment and an electro-pneumatically operated "Heat Pack" door shield assembly

- Complete hot zone is easily removable as a unit for fast maintenance and less down time

- Molybdenum hearth assembly is 18" W x 30" or 36"D

Available:

- Tungsten insulation in Moly Containment

- Graphite and tungsten heating elements

- Graphite insulation in stainless steel containment

- Reinforced hearth assembly

Chamber

- All-stainless steel construction including head-end closures and water-jacketing

- Dual-wall chamber configuration designed to allow complete water-to-surface contact

- Stainless steel dual-wall, water-cooled door

- Water cooling for power feed-thru is external to vacuum chamber, eliminating the possibility of water leaking into the chamber

- Six clamp over center pneumatic clamp/locking door

- Working pressure: Full vacuum to 2-bar (higher pressures available)

Safety Features

All T-M Vacuum Products, Inc. products are equipped with standard safety features to ensure safe operation.

Please consult T-M Vacuum Products, Inc. at (856) 829-2000 for availability and pricing of these or any other option requirements for Pacer high vacuum furnaces.

*All times and pressures are for clean, dry, empty, out-gassed furnaces, starting from ambient pressure and temperature, and may vary. Times and pressures subject to pump size and maximum temperature. Size and weights are approximate.